تشغيل CNC للدفعات الصغيرة: استراتيجيات للجودة والتكلفة المناسبة

المقدمة

مع تقاصر دورات حياة المنتجات وزيادة الطلب على التخصيص، برز التشغيل الدفعي الصغير باستخدام ماكينات CNC كحل تصنيع أساسي. فهو يتيح للشركات إنتاج أجزاء دقيقة عالية الجودة بكميات تتراوح من بضع وحدات إلى بضع مئات، مع التحكم في كلٍ من وقت التسليم والتكاليف.

في Neway Machining يُستخدم إنتاج دفعات CNC صغيرة في مختلف الصناعات، بما في ذلك الطيران، والأجهزة الطبية، والأتمتة الصناعية، مع ضمان جودة مكوّنات ممتازة حتى عند الكميات المنخفضة. تستعرض هذه المدونة الاستراتيجيات التي يمكن لفرق الهندسة والمشترين تطبيقها لتحسين كلٍ من الجودة والجدوى الاقتصادية في التشغيل الدفعي الصغير باستخدام CNC.

قيمة التشغيل الدفعي الصغير باستخدام ماكينات CNC

يوفر التشغيل الدفعي الصغير باستخدام CNC مرونة لا تضاهى. بالنسبة للشركات التي تطوّر نماذج أولية أو تطلق منتجات متخصصة، فإن إنتاج 10 إلى 500 جزء دقيق غالبًا ما يحقق قيمة أكبر من الإنتاج الكمي الضخم.

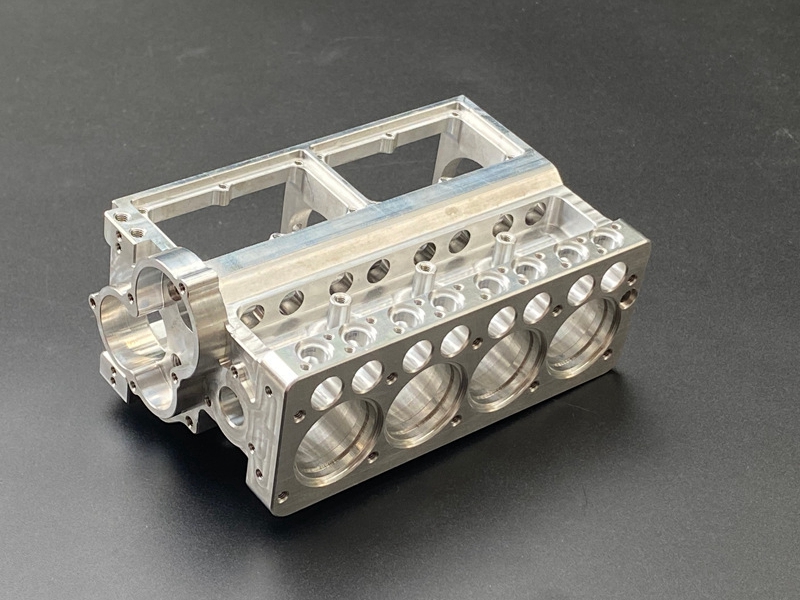

يتجلى ذلك بشكل خاص في قطاعات مثل الطيران والفضاء، حيث تمر مكونات مثل الأجزاء الهيكلية من التيتانيوم أو مسامير إنكونيل بعدة دورات من التعديلات التصميمية. يوفّر التشغيل منخفض الحجم باستخدام CNC الدقة المطلوبة لعمليات التحقق والتصديق، مع تقليل التكاليف المرتبطة بالقوالب والأدوات الصلبة.

وبالمثل، يستفيد قطاع الأجهزة الطبية من الإنتاج الدفعي الصغير باستخدام CNC خلال التجارب السريرية ومراحل الإطلاق المبكر في السوق. يمكن تسليم أجزاء معقدة مصنّعة من مواد متوافقة حيويًا، مثل الزركونيا أو سبائك التيتانيوم، مع التفاوتات المشددة التي تتطلبها المعايير التنظيمية.

أما في مجال الروبوتات والأتمتة، فيُعد التشغيل الدفعي الصغير باستخدام CNC مثاليًا لإنتاج الهياكل المخصصة، وحوامل المشغلات، والتروس الدقيقة — وهي مكوّنات غالبًا ما تكون مطلوبة بكميات منخفضة لمعدات متخصصة.

في كل هذه القطاعات، تكمن القيمة الأساسية للتشغيل الدفعي الصغير باستخدام CNC في تمكين التكرار السريع، وتقليل مخاطر المخزون، ودعم استراتيجيات المنتجات المُفصَّلة بحسب احتياجات السوق.

تخطيط العمليات لتحقيق أقصى قدر من الكفاءة

لتحسين التشغيل الدفعي الصغير باستخدام CNC، يعد التخطيط الدقيق للعملية أمرًا أساسيًا. فاختيار المادة المناسبة من البداية يقلل من زمن التشغيل ويحسّن جودة الأجزاء. على سبيل المثال، اختيار ألمنيوم 6061 للأجزاء الهيكلية خفيفة الوزن يحقق توازنًا بين قابلية التشغيل والقوة، مما يجعله خيارًا اقتصاديًا للعديد من مكونات الطيران والصناعة.

يعزز البرمجة المتقدمة باستخدام CAD/CAM الكفاءة بشكل أكبر. فالتوليد القائم على المحاكاة لمسارات الأدوات يقلل الحركات غير الضرورية للأداة، ويخفض زمن الدورة، ويحسّن التشطيب السطحي. يكون هذا مفيدًا بشكل خاص عند تشغيل سبائك صعبة مثل إنكونيل 625، أو عند تشغيل هندسيات معقدة في المواد السيراميكية.

كما يُعد التثبيت الفعال للقطع (Workholding) عاملًا حاسمًا. تتيح أنظمة التثبيت المعيارية تبديلًا سريعًا بين الأجزاء، وهو أمر ضروري عند تشغيل عدة تصميمات في دفعة واحدة. على سبيل المثال، يقلل استخدام التثبيت المعياري في تشغيل النحاس الأصفر (Brass) باستخدام CNC لمكوّنات الصمامات منخفضة الحجم بشكل كبير من وقت الإعداد، مع ضمان جودة متسقة.

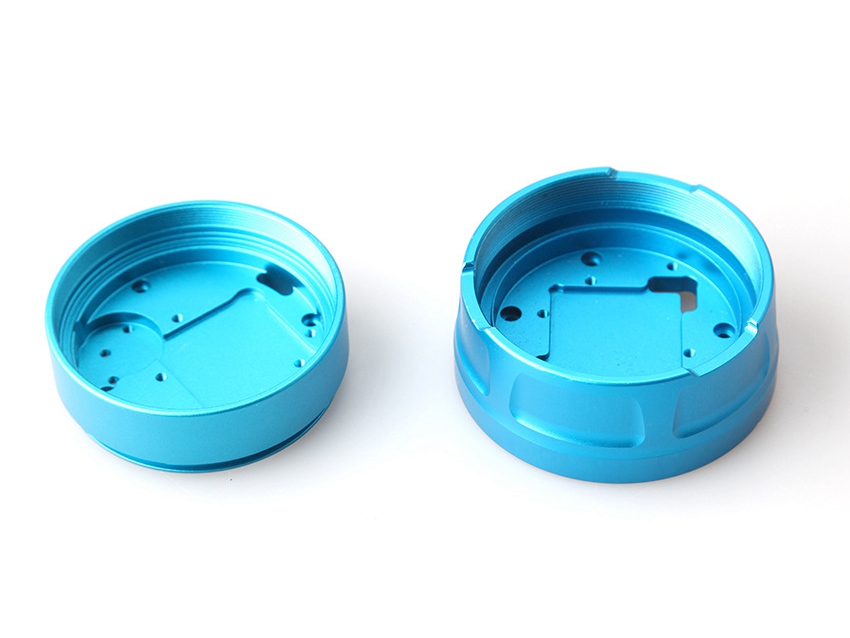

أخيرًا، يضيف دمج عمليات تشطيب سطحي ملائمة قيمة إضافية دون تكلفة مفرطة. فاختيار تشطيبات مستهدفة مثل الأكسيد الأسود لأجزاء الفولاذ، أو الأنودة لمكونات الألمنيوم، يحسن الوظيفة والمظهر الجمالي بطريقة مضبوطة.

استراتيجيات خفض التكاليف في إنتاج دفعات CNC صغيرة

الاستخدام الفعّال للمواد

يؤثر اختيار المواد وكيفية استخدامها بشكل كبير في تكلفة التشغيل الدفعي الصغير باستخدام CNC. حيث يجب على المهندسين، كلما أمكن، اختيار أبعاد خامات (Stock) تقلل الفاقد. فاستخدام صفائح أو قضبان ألمنيوم 7075 بأبعاد قريبة من الشكل النهائي للجزء يقلل من زمن التشغيل وتكلفة المادة.

في بعض الحالات، يمكن للمواد المُقسّاة مسبقًا (Pre-hardened) أن تُلغي الحاجة إلى معالجة حرارية بعد التشغيل. فاختيار فولاذ 4140 في حالة مُقسّاة مسبقًا يُبسّط الإنتاج للمكونات عالية المتانة في قطاع السيارات أو المعدات الصناعية.

تحسين الأدوات والبرمجة

تمدّد الأدوات عالية الجودة من عمر الأداة وتحسّن كفاءة التشغيل. تُعد أدوات الكربيد المطلية فعّالة بشكل خاص عند تشغيل مواد كاشطة مثل هاستيلوي C-22 أو الفولاذ المقاوم للصدأ.

بالإضافة إلى ذلك، يقلل تحسين مسارات الأدوات من زمن الدورة. يمكن لبرامج CAM محاكاة أحمال الأداة والتوصية بقيم تغذية وسرعات مثالية. يُعد هذا مهمًا بشكل خاص في الهياكل الرقيقة في مجال الطيران، حيث يمكن أن يؤدي الضغط الزائد للأداة إلى تشوّه الجزء.

التثبيت الذكي وتقليل زمن الإعداد

في التشغيل الدفعي الصغير باستخدام CNC، يشكّل زمن الإعداد نسبة كبيرة من التكلفة الإجمالية. تتيح أنظمة التثبيت المعيارية تبديلًا أسرع للأجزاء، مما يحسن استغلال وقت تشغيل الماكينة. فعند تشغيل دفعات صغيرة ومتنوعة، مثل هياكل حسّاسات الروبوتات أو حوامل الأتمتة، تقلل التركيبات سريعة التغيير بشكل كبير من وقت التوقف بين المهام.

يمكن أن تحسّن التركيبات المخصصة — التي تُنتَج أحيانًا عبر التشكيل السريع (Rapid Molding) — عمليات الإعداد لأجزاء معقدة أو حساسة. على سبيل المثال، يستفيد تشغيل نموذج أولي لهيكل من مادة PEEK لجهاز طبي من تركيب مُصمَّم خصيصًا وفق هندسة الجزء ومتطلبات التفاوت.

اختيارات استراتيجية للتشطيب السطحي

يمكن أن تكون عمليات التشطيب السطحي مساهمًا كبيرًا في التكلفة إذا تم تحديدها بشكل مبالغ فيه. لذلك ينبغي على المهندسين مواءمة التشطيب مع متطلبات وظيفة الجزء. ففي الأجزاء الداخلية أو النماذج الأولية الوظيفية، قد يكون تشطيب As-Machined كافيًا، بينما قد تحتاج الأجزاء المواجهة للعميل أو المكونات العاملة في بيئات تآكل قاسية إلى التلميع الكهربائي أو طلاءات الحواجز الحرارية.

من خلال اختيار عمليات التشطيب الضرورية فقط، يمكن للمشترين خفض تكلفة الوحدة بشكل ملحوظ دون التضحية بالأداء.

الاستفادة من التعاون مع الموردين

في النهاية، يحقق التعاون المبكر مع موردي خدمات CNC أفضل النتائج. يمكن للموردين ذوي الخبرة مثل Neway Machining اقتراح تعديلات تصميمية تُبسّط التشغيل وتقلل التكاليف. فمثلًا، يمكن لتعديل سماكة الجدار أو إضافة تجاويف تفريغ أن يحسن وصول الأداة، خصوصًا في الجيوب العميقة أو الميزات الداخلية.

كما يتيح التعاون مع الموردين تقديم عروض أسعار دقيقة. تضمن مراجعات DFM (التصميم للتصنيع) المفصّلة احتساب جميع عوامل التكلفة — مثل نوع المادة، والتفاوتات، والتشطيبات — في عرض السعر. هذه الشفافية تصب في مصلحة كلٍ من المشترين والمصنّعين.

التحكم في العمليات وضمان الجودة في التشغيل الدفعي الصغير باستخدام CNC

معايرة الماكينات والصيانة

تبدأ الدقة في التشغيل الدفعي الصغير باستخدام CNC بالحفاظ على دقة الماكينة نفسها. تُعد معايرة محاور الماكينة ومحاذاة المغزل بشكل منتظم أمرًا بالغ الأهمية، خاصة عند تشغيل مكونات ذات تفاوتات مشددة مثل أدوات جراحية من سيراميك الزركونيا أو حوامل تيتانيوم لمجال الطيران.

تضمن المعدات المُعتنى بها جيدًا تحقيق تفاوتات مشددة تصل إلى ±0.005 مم بشكل متكرر. تساعد جداول الصيانة الوقائية في تجنب انجراف الأبعاد والتوقفات غير المخطط لها، وهما عاملان حاسمان في الدفعات الصغيرة ذات مواعيد التسليم القصيرة.

التحقق من مسارات الأدوات والمحاكاة

بالنسبة للهندسيات المعقدة، يعد التحقق من مسارات الأدوات باستخدام برامج المحاكاة أمرًا ضروريًا. يمكن لبرامج CAM المتقدمة اكتشاف احتمالات التصادم وتحسين استراتيجيات القطع. يكون هذا مهمًا بشكل خاص عند تشغيل أجزاء رقيقة الجدران في قطاع الطيران مصنوعة من مواد مثل Rene 41، والتي تميل إلى التصلب بالتشغيل (Work Hardening) والتشوه.

تساعد المحاكاة أيضًا في تحديد المناطق التي يمكن فيها تحسين التشطيب السطحي، مما يتيح إجراء تعديلات برمجية قبل البدء في التشغيل الفعلي.

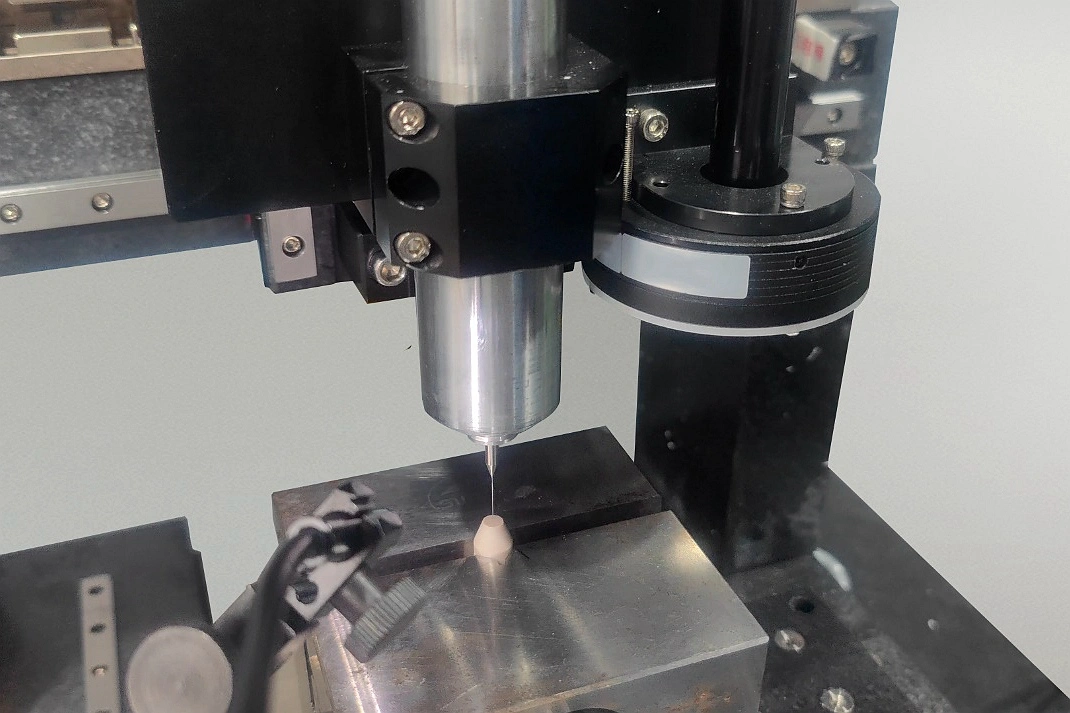

الفحص أثناء التشغيل والمراقبة

يلعب الفحص أثناء العملية دورًا رئيسيًا في ضمان جودة متسقة خلال الإنتاج الدفعي الصغير. إذ تُجهَّز العديد من ماكينات CNC بمجسات لمس أو أنظمة قياس ليزرية تتيح التحقق من الأبعاد الحرجة أثناء الدورة.

على سبيل المثال، عند إنتاج أجزاء دقيقة لـأتمتة المعدات الصناعية، يضمن الفحص أثناء التشغيل باستخدام المجسات بقاء ميزات مثل مقاعد المحامل أو ثقوب المحاذاة ضمن حدود التفاوت طوال الدفعة.

توفر أنظمة مراقبة العملية التي تتتبع حمل المغزل والاهتزاز ودرجة الحرارة مستويات إضافية من التحكم. يمكن لهذه الأنظمة اكتشاف تآكل الأدوات أو العيوب المادية مبكرًا، ما يمنع الهدر ويقلل من أعمال الإصلاح.

القياس والتحقق بعد التشغيل

بعد اكتمال التشغيل، تتحقق عمليات الفحص الصارمة من مطابقة الأجزاء للمواصفات. ففي الدفعات الصغيرة من المكونات الحرجة، مثل الأجزاء الهيكلية من الفولاذ الكربوني المُشغَّل باستخدام CNC للتطبيقات النووية، يشمل الفحص عادة:

قياسات أبعاد باستخدام CMM

قياس خشونة السطح

اختبارات الصلادة

فحص بصري للعيوب الشكلية والجمالية

يضمن توثيق نتائج الفحص إمكانية التتبع ويوفّر طمأنينة للعملاء في الصناعات المنظمة مثل الطيران، والطب، والطاقة النووية.

توثيق العمليات وقابلية التكرار

يُعد توثيق جميع تفاصيل عملية التشغيل مفتاحًا لتحقيق نتائج قابلة للتكرار في الإنتاج الدفعي الصغير. يشمل ذلك:

أوراق إعداد تفصيلية (Setup Sheets)

قوائم الأدوات وقيم الإزاحة (Offsets)

تصاميم التركيبات (Fixtures)

خطط الفحص

على سبيل المثال، عند إنتاج موصلات كهربائية نحاسية C110 مخصصة لمنتجات إلكترونية استهلاكية، يضمن توثيق العملية أن الدفعات المستقبلية ستحافظ على نفس المعايير البعدية والجمالية.

علاوة على ذلك، تُسهل الوثائق الواضحة عملية التوسّع. فإذا تحوّل طلب أولي لـ 50 جزءًا إلى تشغيل إنتاجي من 500 جزء، يمكن توسيع العملية المُحققة بسرعة مع الحد الأدنى من مخاطر الانحراف.

استراتيجيات الشراء والاتجاهات المستقبلية في التشغيل الدفعي الصغير باستخدام CNC

اختيار المورّد المناسب

يُعد اختيار مورّد كفؤ أمرًا حاسمًا لتحقيق الجودة والجدوى الاقتصادية في التشغيل الدفعي الصغير باستخدام CNC. ينبغي على المشترين تقييم الموردين بناءً على:

نطاق العمليات: هل يستطيع المورّد التعامل مع مواد وعمليات متعددة، مثل تشغيل التيتانيوم باستخدام CNC أو الحفر العميق للتطبيقات الجوية؟

خيارات التشطيب السطحي: هل يقدّم خدمات متكاملة مثل طلاء التفلون أو التلميع المخصص للمنتجات الموجهة للمستهلك؟

الخبرة الصناعية: يجلب الموردون ذوو الخبرة المثبتة في قطاعات مثل النفط والغاز أو السيارات رؤى قيّمة في مجالات التصميم وقابلية التصنيع.

يساعد تقييم الأداء السابق عبر دراسات حالة مثل تشغيل سبائك فائقة بدقة عالية لقطاع النفط والغاز المشترين على قياس كفاءة المورّد.

التركيز على التصميم للتصنيع (DFM)

يجب على فرق الشراء إشراك مورّدي CNC في وقت مبكر من عملية التصميم. يمكن لمراجعات التصميم للتصنيع (DFM) تحديد فرص خفض التكاليف، مثل:

تقليل التفاوتات المشددة غير الضرورية

تعديل الميزات بما يسمح باستخدام أدوات قياسية

اختيار مواد بديلة، مثل التحويل من ألمنيوم 2024 إلى ألمنيوم 6061 لبعض المكونات غير الحرجة

يؤدي التعاون المبكر إلى أجزاء أسهل في التشغيل وأكثر اقتصادًا في الإنتاج.

عروض أسعار شفافة وتفصيل التكاليف

تعزز عمليات التسعير الشفافة الثقة بين المشترين والموردين. يجب أن تتضمن عروض الأسعار التفصيلية توضيحًا لـ:

زمن التشغيل على الماكينات

تكاليف المواد

عمليات التشطيب السطحي

متطلبات الفحص والتوثيق

على سبيل المثال، ينبغي أن يوضح عرض سعر لأجسام صمامات مصنّعة من نحاس C360 باستخدام CNC الفروق بين التشغيل، وإزالة الزوايا الحادة، وعمليات التلميع بالاهتزاز (Tumbling)، مما يتيح للمشترين اتخاذ قرارات واعية بشأن المقايضات المحتملة.

الاتجاهات المستقبلية: الرقمنة والأتمتة

تُحوِّل الاتجاهات الناشئة مشهد التشغيل الدفعي الصغير باستخدام CNC:

سير العمل الرقمي: تعزز منصات إدارة المشاريع القائمة على السحابة التواصل بين الشركات المصنعة الأصلية (OEMs) والموردين، مما يسرّع تسليم النماذج الأولية والدفعات القصيرة.

التصنيع الهجين: يتيح الجمع بين الطباعة ثلاثية الأبعاد والتشغيل باستخدام CNC هندسيات مبتكرة وتوفيرًا في التكاليف في تطبيقات مثل توليد الطاقة.

الاستدامة: يعتمد المصنّعون ممارسات مستدامة، مثل تحسين استخدام المواد في تشغيل البولي كربونات باستخدام CNC) وإعادة تدوير الرايش الناتج من معادن مثل نحاس البيريليوم.

الإنتاج المحلي وسلاسل الإمداد المرنة

يقلل الإنتاج المحلي لدفعات CNC صغيرة من أوقات التسليم وتكاليف الخدمات اللوجستية. ويُعد ذلك ذا قيمة خاصة في الصناعات ذات دورات التصميم السريعة مثل المنتجات الاستهلاكية، حيث تمثّل المرونة ميزة تنافسية.

يقدّم الموردون القادرون على التوسع من النموذج الأولي إلى الإنتاج — مع توفير كلٍ من التصنيع منخفض الحجم والإنتاج الكمي — قيمة طويلة الأمد من خلال دعم الطلبات المتغيرة على المنتجات.